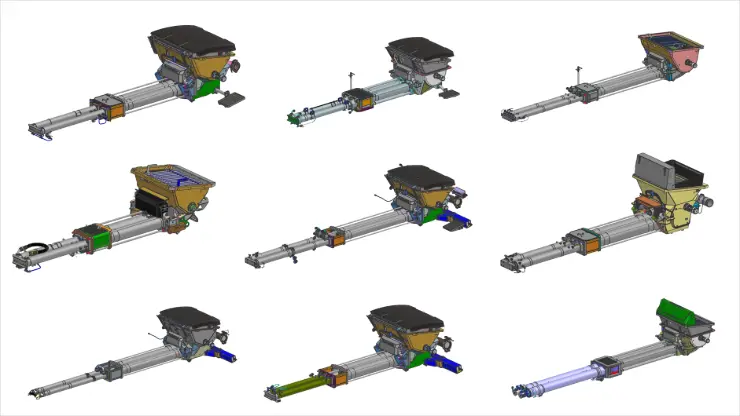

Herbert Hänchen

Herbert Hänchen GmbH is a long-established, internationally active family business with around 200 employees. Since 1925, the company has been synonymous with high-precision hydraulic cylinders, drive systems, and special solutions in testing technology.

Successful migration from Oracle to MSSQL

Since 1995, Dr. Wallner Engineering GmbH has been supporting Körber AG in various PLM projects – from migrations and method development to training and multi-site consolidations. Another key project followed in 2024: the migration of the Teamcenter database from Oracle to Microsoft SQL Server (MSSQL).

The challenge

Due to technical and licensing requirements, particularly when using virtual environments, the existing Oracle infrastructure had to be replaced. After evaluating various approaches, the direct table migration method was chosen because it enables short rollout times and maximum control.

The solution

The project included preparing the infrastructure, an OOTB Teamcenter installation, test migration, customer testing, and the productive rollout. Data was transferred via CSV export and import, which proved to be the most efficient method for large amounts of data. Parallel processing of multiple tables further reduced the runtime. After a four-week test phase, the productive migration was successfully completed – without the need for a fallback, as the Oracle source remained unchanged.

The result

The migration went smoothly and on schedule. During the subsequent stabilization phase, performance optimizations were implemented to further increase system efficiency. All migrated databases are running stably and error-free – proof of the high quality and reliability of the solution used.

Would you also like to migrate your production environment or implement modern processes? How can outdated methods be replaced? Let's find out together. Book a free consultation with an expert from our team.